Post Croix - Monza GSE

Hi Ian,

How would you advance the body for (~8 cm) 3 inches ?

It is not easyier to cut at some place and made three parts, I think cut in the sills and in the middle of the roof ?

Chris

How would you advance the body for (~8 cm) 3 inches ?

It is not easyier to cut at some place and made three parts, I think cut in the sills and in the middle of the roof ?

Chris

Dernière modification par Mycroft le mar. 06 oct., 2015 22:52, modifié 1 fois.

"Si la connerie était une forme d'énergie gratuite, je pourrais dire sans le moindre doutes que l'on en manquerait certainement jamais ... Elle est inépuisable"

-- Christopher PIRSON

-- Christopher PIRSON

-

Bstardchild

- Messages : 151

- Inscription : dim. 08 févr., 2009 19:13

- Localisation : Land of "Roast Beef" and "Jelly"

sixenligne a écrit : ↑mar. 06 oct., 2015 20:55Awesome !

The roll cage is not going to be too small ? (relative to the body?)

I think that's perspective in the shots - it's closer than it looks and the body does need to come down a fair way

-

Bstardchild

- Messages : 151

- Inscription : dim. 08 févr., 2009 19:13

- Localisation : Land of "Roast Beef" and "Jelly"

Mycroft a écrit : ↑mar. 06 oct., 2015 22:52Hi Ian,

How would you advance the body for (~8 cm) 3 inches ?

It is not easyier to cut at some place and made three parts, I think cut in the sills and in the middle of the roof ?

Chris

Hi Chris

No need to cut it just needs to move forward - I want the rear wheel in the middle of the rear arch before I check where the front wheel is in the front arch - then I'll compromise till I'm happy with both wheels in the arches

Right now Rear wheel is like this in the arch

| O|

this would be better

| O |

But I have to make sure the front also works OK - it should be perfect if the rear is centred the wheelbase is the same after all.....

Dernière modification par Bstardchild le mer. 07 oct., 2015 00:22, modifié 1 fois.

Hello my friend! You still working!

<img src='http://i.imgur.com/XoORj2n.png' border='0' alt='user posted image' /><a href='https://zupimages.net/viewer.php?id=20/02/rycu.jpg' target='_blank'><img src='https://zupimages.net/up/20/02/rycu.jpg' border='0' alt='user posted image' /></a><img src='http://i.imgur.com/lLj3qas.jpg' border='0' alt='user posted image' />

[i:472p3]F☆ck new cars,I'm drivin' old school ! [/i:472p3]

[i:472p3]F☆ck new cars,I'm drivin' old school ! [/i:472p3]

-

Bstardchild

- Messages : 151

- Inscription : dim. 08 févr., 2009 19:13

- Localisation : Land of "Roast Beef" and "Jelly"

Yeah still working

Winter is bad weather - no shows, track days or runs and nothing gets in the way of progress so progress is much faster.

-

Bstardchild

- Messages : 151

- Inscription : dim. 08 févr., 2009 19:13

- Localisation : Land of "Roast Beef" and "Jelly"

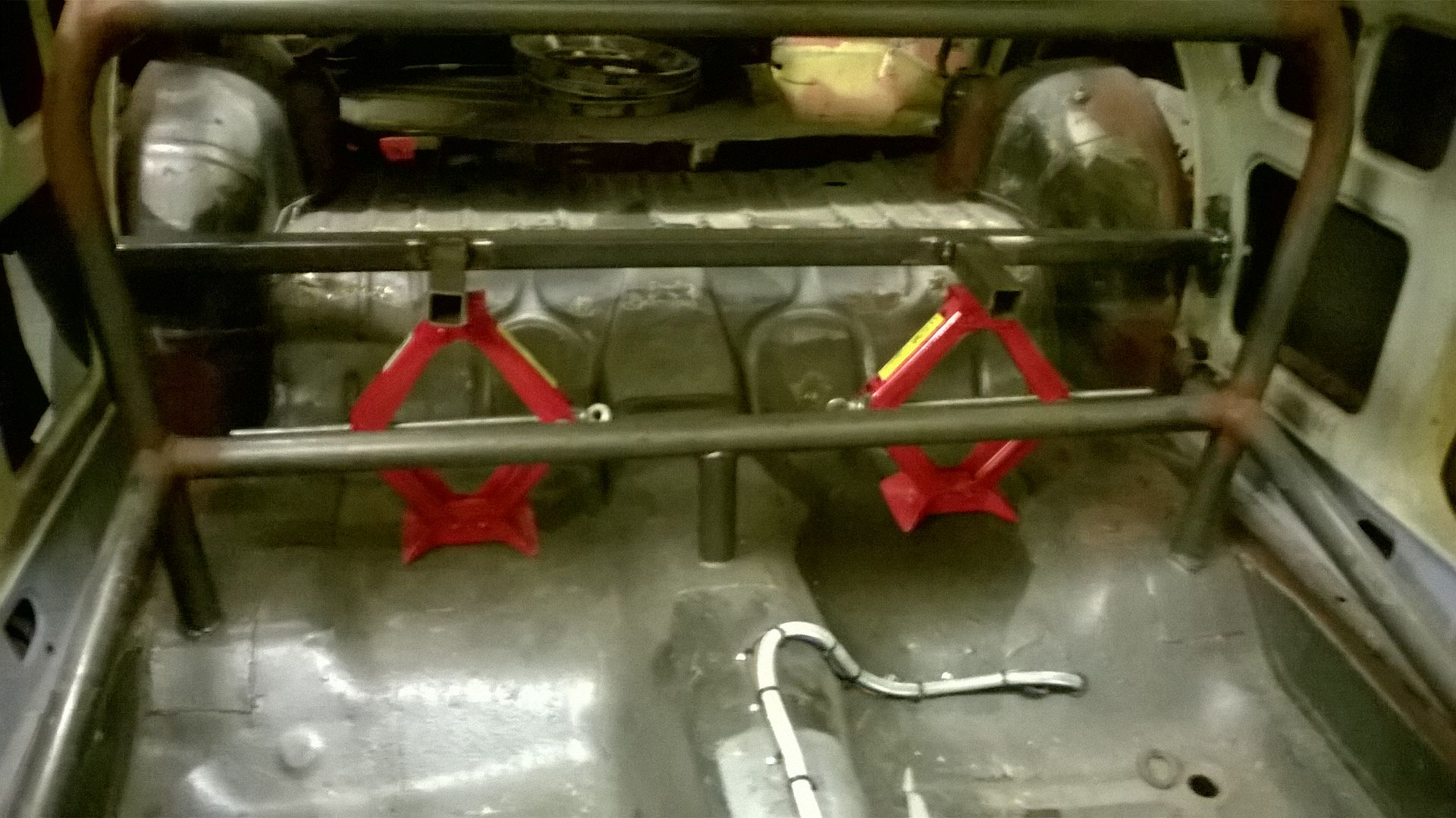

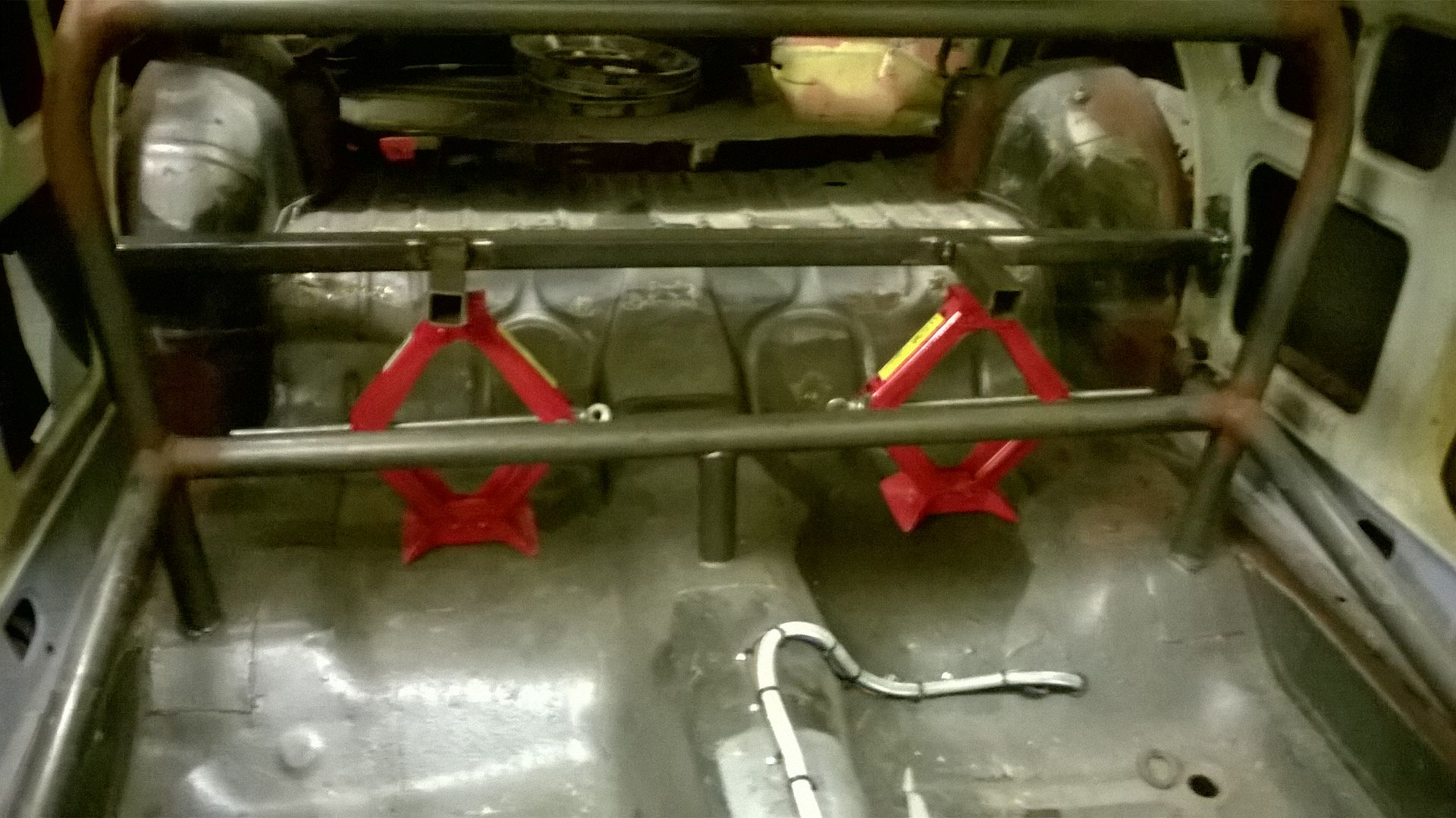

OK a suggestion from another forum I use regarding my up and down requirements (I really can't rely on my three first fitment helpers every time it needs to go up or down) scissor jacks - great idea I thought - so I bought 4 new ones

Intention was to use two at the back and one or maybe 2 at the front depending on how well it worked out

So I mig'd in a 140mm 40x40 box section in across the back (I needed to consider that the body still needs to move forward 3 inches)

So then I thought I'll jack the back end and see what I need to do with the front

Hmmmm wasn't expecting that - the whole shell was lifting evenly front and rear with just the two rear scissors in use

Oh well carry on and see if it gets a bit tippy as I go higher - then I can almost certainly get away with just adding a bit of support/lifting capability at the front............

Or not...... I guess I've found the centre of effort!!!

So I got one side of the floor pan folded up to allow the body to slide over and dropped it down

Needs to go down another 4 inches but it can't right now

- The parcel shelf is fouling the rear section of the cage

- The scuttle is fouling the front section of the cage

- The "boot floor" is fouling on the "boot floor"

So until I have both sides over the step I'm not cutting yet - space is a bit tight in the other side of the garage so I may well push it out and turn it round so I have better access

Intention was to use two at the back and one or maybe 2 at the front depending on how well it worked out

So I mig'd in a 140mm 40x40 box section in across the back (I needed to consider that the body still needs to move forward 3 inches)

So then I thought I'll jack the back end and see what I need to do with the front

Hmmmm wasn't expecting that - the whole shell was lifting evenly front and rear with just the two rear scissors in use

Oh well carry on and see if it gets a bit tippy as I go higher - then I can almost certainly get away with just adding a bit of support/lifting capability at the front............

Or not...... I guess I've found the centre of effort!!!

So I got one side of the floor pan folded up to allow the body to slide over and dropped it down

Needs to go down another 4 inches but it can't right now

- The parcel shelf is fouling the rear section of the cage

- The scuttle is fouling the front section of the cage

- The "boot floor" is fouling on the "boot floor"

So until I have both sides over the step I'm not cutting yet - space is a bit tight in the other side of the garage so I may well push it out and turn it round so I have better access

-

Bstardchild

- Messages : 151

- Inscription : dim. 08 févr., 2009 19:13

- Localisation : Land of "Roast Beef" and "Jelly"

So where was I....................

Needs to go down another 4 inches but it can't right now

- The parcel shelf is fouling the rear section of the cage

- The scuttle is fouling the front section of the cage

- The "boot floor" is fouling on the "boot floor"

So until I have both sides over the step I'm not cutting yet - space is a bit tight in the other side of the garage so I may well push it out and turn it round so I have better access

Well I jacked up the back and dragged it across the garage to make some room and got stuck in before I hit my power tool curfew

Other side sill is now over - not all the way down but it's over and that's much better - arch gap has closed

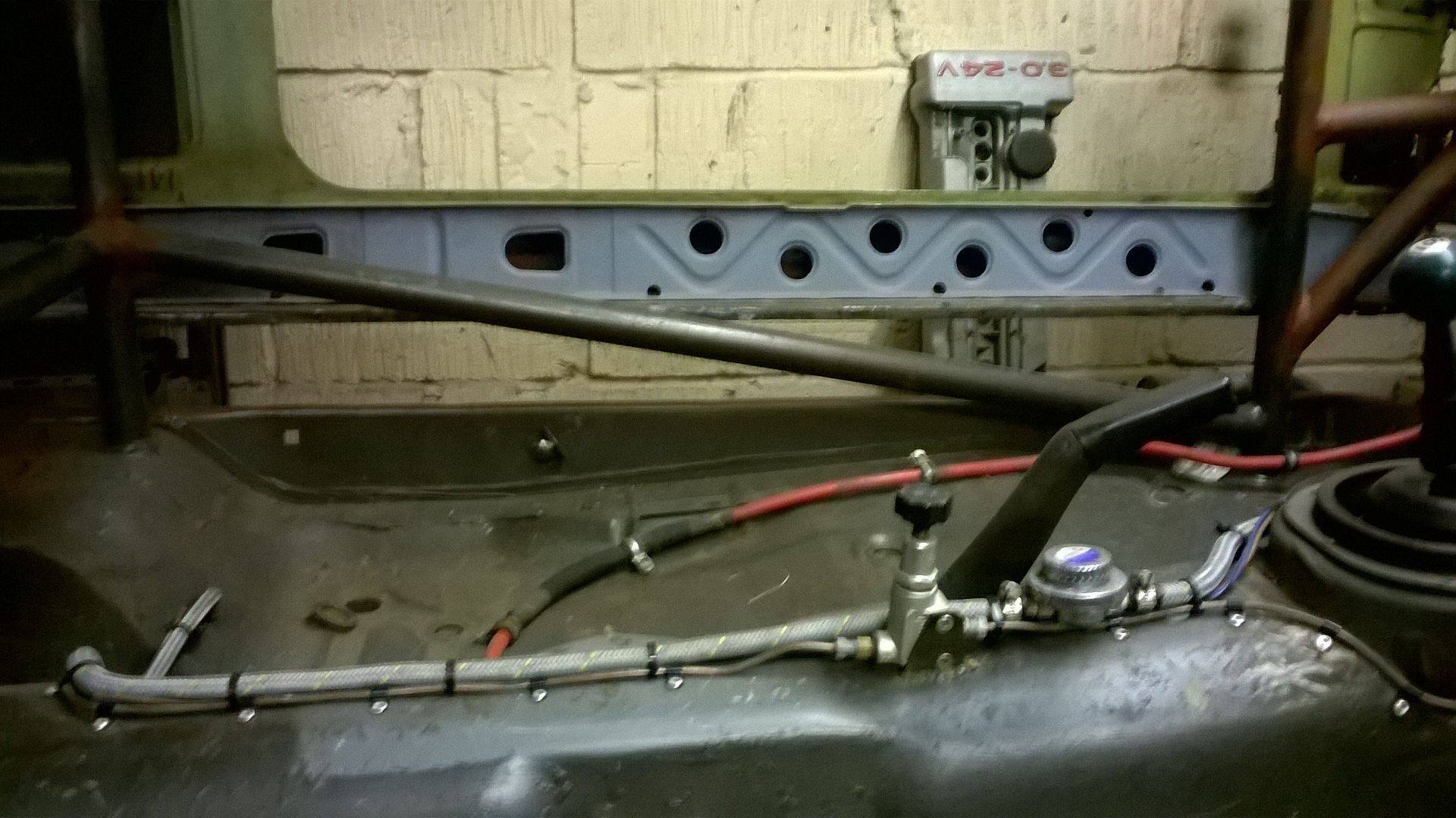

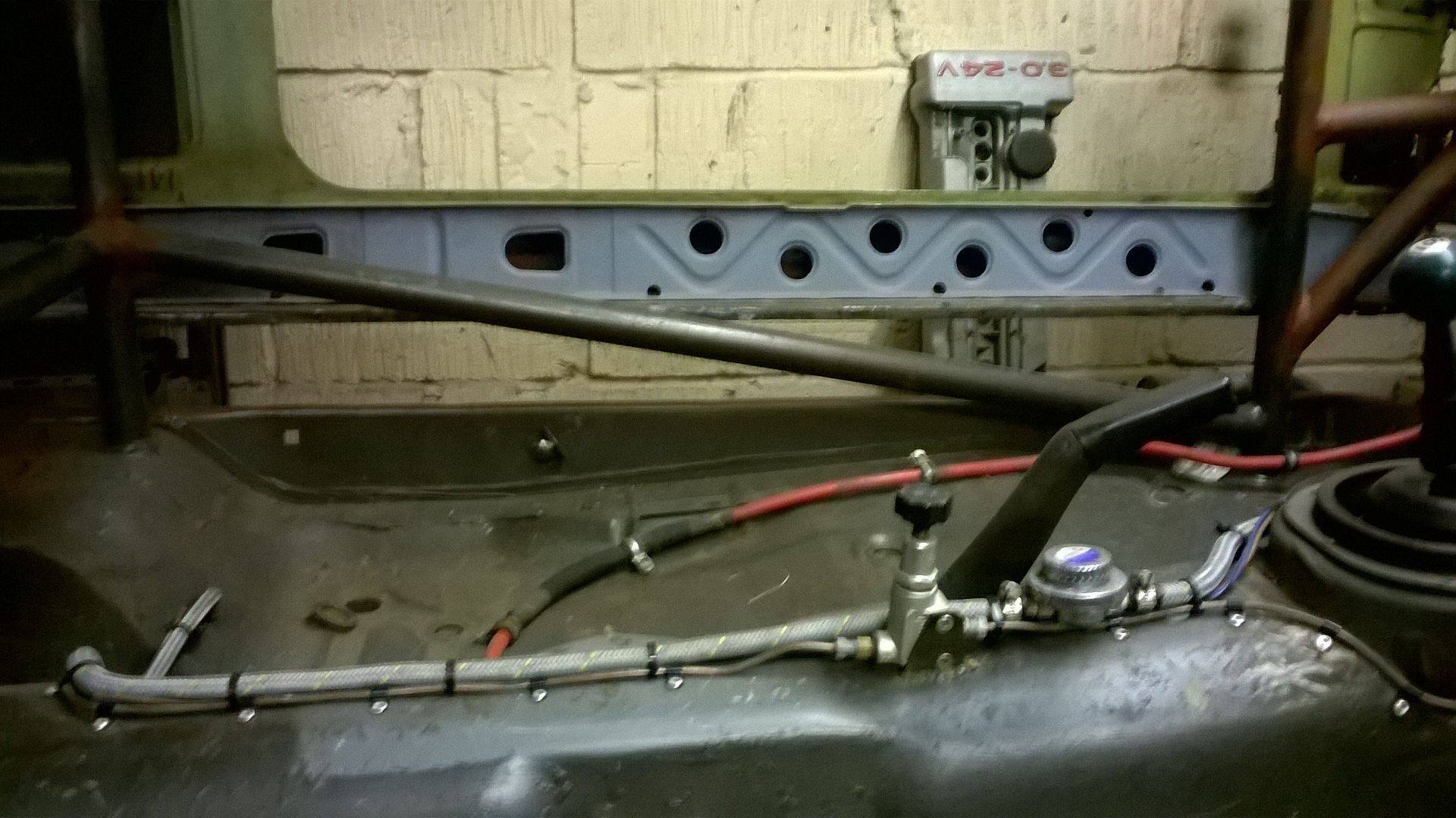

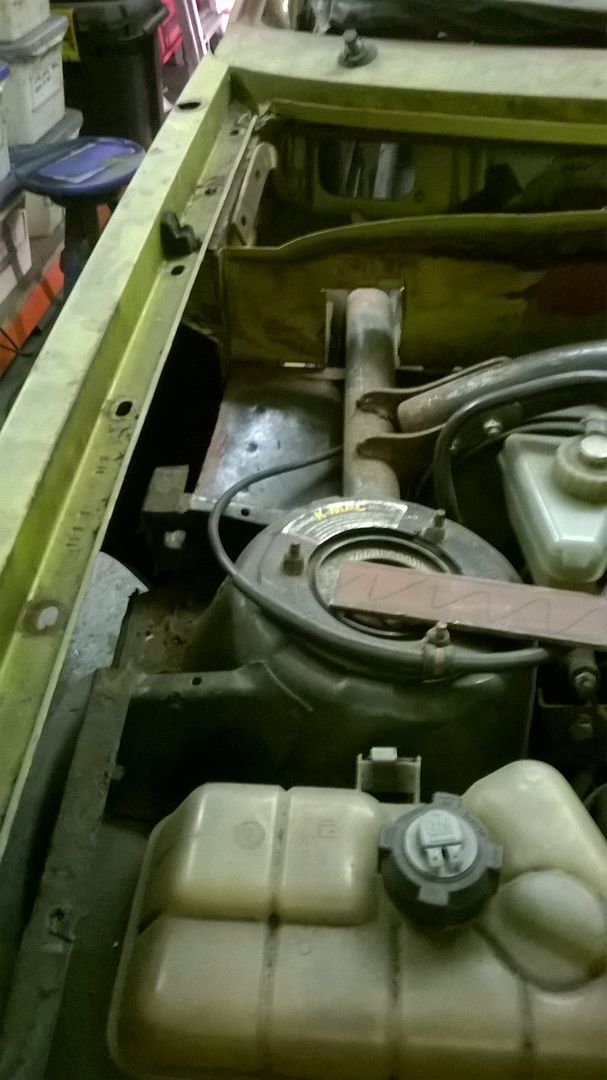

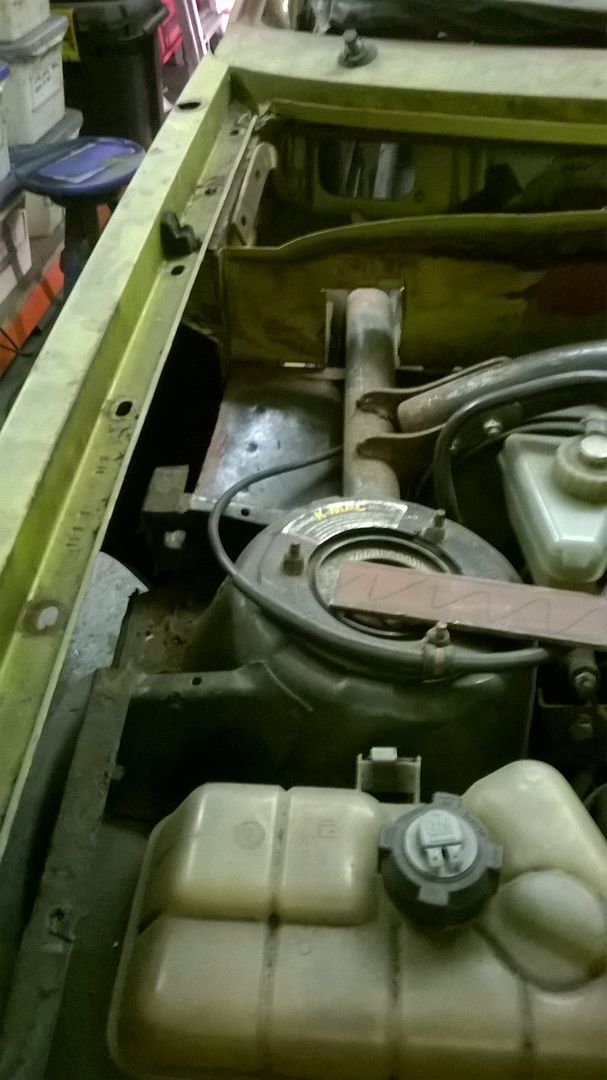

So Boot floor

Solution

Slightly drastic but I looked at my issues for a while and got the tank down and had a measure up - I have a bad memory of a wet track day where I spent a lot of time getting very wet and cold while I fixed an issue with a fuel pump and filter - the commodore boot floor if I left it would be 4 inches lower than the Monza floor level and I had an alloy fuel tank made to hang under the boot floor - a floor 4 inches lower and that's not gonna fit so better plan is build a new boot floor incorporating the tank, pump and filtration - oh and a swirl pot and lift pump wouldn't be a bad thing either.

Oh and once I got the other side down and the shell level I chopped a couple of chunks out of the parcel shelf and that got the arch gap down

So back end down - front end still sitting on the cage where it links to the turrets - I knew what was needed here

Now that's looking better - still a fair few inches to come down yet but it's going in the right direction

Needs to go down another 4 inches but it can't right now

- The parcel shelf is fouling the rear section of the cage

- The scuttle is fouling the front section of the cage

- The "boot floor" is fouling on the "boot floor"

So until I have both sides over the step I'm not cutting yet - space is a bit tight in the other side of the garage so I may well push it out and turn it round so I have better access

Well I jacked up the back and dragged it across the garage to make some room and got stuck in before I hit my power tool curfew

Other side sill is now over - not all the way down but it's over and that's much better - arch gap has closed

So Boot floor

Solution

Slightly drastic but I looked at my issues for a while and got the tank down and had a measure up - I have a bad memory of a wet track day where I spent a lot of time getting very wet and cold while I fixed an issue with a fuel pump and filter - the commodore boot floor if I left it would be 4 inches lower than the Monza floor level and I had an alloy fuel tank made to hang under the boot floor - a floor 4 inches lower and that's not gonna fit so better plan is build a new boot floor incorporating the tank, pump and filtration - oh and a swirl pot and lift pump wouldn't be a bad thing either.

Oh and once I got the other side down and the shell level I chopped a couple of chunks out of the parcel shelf and that got the arch gap down

So back end down - front end still sitting on the cage where it links to the turrets - I knew what was needed here

Now that's looking better - still a fair few inches to come down yet but it's going in the right direction

-

Bstardchild

- Messages : 151

- Inscription : dim. 08 févr., 2009 19:13

- Localisation : Land of "Roast Beef" and "Jelly"

Well a bit more progress some highs and lows....... Oh and tonight's update is brought to you by the majority portrait government and has a further 4 years in office (bloody phone cameras)

So got an early start in the garage - Mrs BC was getting her hair done - no I couldn't notice the difference - yes she did ask (she does every time) and I'll never understand why this response is wrong - after all I cut a bit of steel out of a car I don't ask her if it looks better!!!

Sorry I wandered off topic back to the proper subject

I cleaned up the boot floor edges

I do like to feel I got my money's worth out of flap discs

Then I fired up the plasma cutter and got rid of some small bits that were stopping movement

Then I cut a bit of box section and welded it in so I could use the scissor jacks in a different direction

Windy windy

Carpier picture but you get the idea

Now we are cooking with gas or maybe not - front of the rear wheel arch

Another carpy picture

Much better however I was concerned by the increasing gap at the front (there is a very good reason for this)

Tried on a wing to see how the front wheel sits in the arch

Err needs hitting with a big tree not a stick and I need wider alloys not fibreglass arches.......

Bulk head end - the picture becoming clearer

Really clear

The joint needs to be 2 inches lower!!! The Shell is too high at the front by 2 inches and if i can get it down it'll close the wheel arch gap bring the shell lower at the bulkhead and make the two sills run in parallel and maybe if I'm really lucky I can fit the dash in behind the front of the cage - cos right now it doesn't

So got an early start in the garage - Mrs BC was getting her hair done - no I couldn't notice the difference - yes she did ask (she does every time) and I'll never understand why this response is wrong - after all I cut a bit of steel out of a car I don't ask her if it looks better!!!

Sorry I wandered off topic back to the proper subject

I cleaned up the boot floor edges

I do like to feel I got my money's worth out of flap discs

Then I fired up the plasma cutter and got rid of some small bits that were stopping movement

Then I cut a bit of box section and welded it in so I could use the scissor jacks in a different direction

Windy windy

Carpier picture but you get the idea

Now we are cooking with gas or maybe not - front of the rear wheel arch

Another carpy picture

Much better however I was concerned by the increasing gap at the front (there is a very good reason for this)

Tried on a wing to see how the front wheel sits in the arch

Err needs hitting with a big tree not a stick and I need wider alloys not fibreglass arches.......

Bulk head end - the picture becoming clearer

Really clear

The joint needs to be 2 inches lower!!! The Shell is too high at the front by 2 inches and if i can get it down it'll close the wheel arch gap bring the shell lower at the bulkhead and make the two sills run in parallel and maybe if I'm really lucky I can fit the dash in behind the front of the cage - cos right now it doesn't

My respect to Mrs BC, there's no thing you can answer correctly to a woman (and even more to yours) asking you something about herself except may be that she always have a good sight

At this point of your project, every little detail show you you're progressing in a good way ! Good job !

At this point of your project, every little detail show you you're progressing in a good way ! Good job !

Dernière modification par Mycroft le ven. 16 oct., 2015 01:00, modifié 1 fois.

"Si la connerie était une forme d'énergie gratuite, je pourrais dire sans le moindre doutes que l'on en manquerait certainement jamais ... Elle est inépuisable"

-- Christopher PIRSON

-- Christopher PIRSON